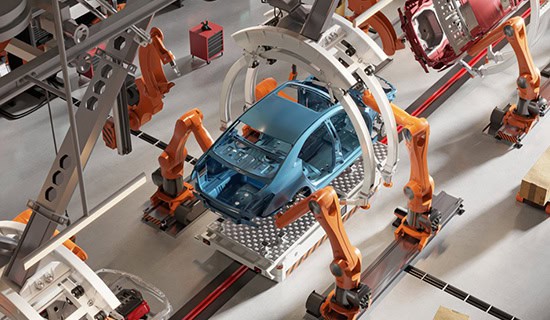

Smart Manufacturing for Automotive

-

In-Cabin Sensing has Automakers Looking Inward

In 2025, in-cabin sensing is the underlying foundation needed for legal compliance, semi-autonomous driving, safety ratings, and the premium user experience consumers now expect.

Read more -

Driving Toward Industry 5.0: An Automotive Manufacturing Perspective

Industry 5.0 represents more than just a technological shift; it’s a philosophical change in how the industry views manufacturing. It demands that automakers blend innovation with empathy, efficiency with sustainability, and precision with creativity.

Read more -

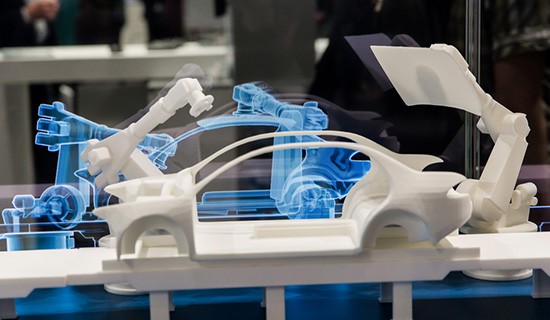

The automotive executive’s guide to digital manufacturing

Learn how to virtualize your product launches and predict potential issues before they arise. By building a digital twin of production and performance, you’ll achieve digital continuity—from design to delivery.

Download now

Trending Now

Advanced strategies for line automation engineering in automotive

Learn how to overcome industry challenges and stay ahead with proven strategies for next-level automation, virtual verification, and data-driven production, in this eBook.

Production Operation and Optimization for Automotive

The rising complexity in automotive production requires flexibility, scalability, faster time-to-market and sustainability in the shopfloor operations. It needs next-level automation.

Use Cases

Navigating Smart Manufacturing in 2025: Key Challenges for the Auto Industry

A look at the top 2025 smart auto manufacturing issues related to automation, digital transformation, robotics, embedded AI, and more.

Smart Manufacturing in the Automotive Industry

Learn how auto manufacturers are addressing various challenges they face with smart manufacturing in this state of the market report.

Riding Out Automotive Market Uncertainty with Digital Twins

A critical aspect of using digital twins is that they can complement traditional forecasting and prescriptive tools by incorporating real-time monitoring and simulations.

Using Fuzzy Logic and AI to Improve Supply Chain Efficiency

The integration of fuzzy logic and AI presents significant opportunities for organizations like smart automotive manufacturers to enhance their supply chain management practices.

Digital Twins, IT/OT Convergence Drive the Industrial Internet

Digital twins offer a way to apply advanced analytics to derive insights that, in turn, drive optimization of production and operation processes.

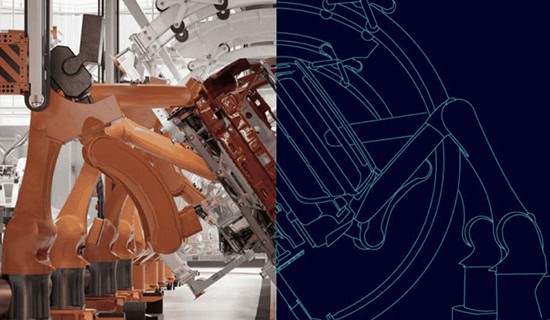

Smart Manufacturing: Melding Digital and Physical Worlds

Smart manufacturing helps automakers achieve greater efficiency and accelerate innovation by blending digital technologies with the physical realm, making it possible to accomplish things we’ve never seen before.

You Can’t Spell Smart Manufacturing Without AI

AI helps smart manufacturers use the vast amounts of data being generated from IoT devices and smart sensors throughout their factory.

Not Your Father’s Auto Industry: Why Smart Manufacturing is Needed as We Head into 2024

Smart manufacturing technologies like digital twins, virtual commissioning, and more can bring about the required changes to move the industry forward in the years to come.

How Smart Technologies are Helping Simplify Sustainability in Auto Manufacturing

Smart technologies are emerging as a powerful simplifying force amid the complexities of pursuing sustainability goals.

How Smart Manufacturing Makes Smart Autos Possible

Automakers are using virtual commissioning, digital twins, advanced supply chain management, and more to meet ever-changing customer demands for smart autos.

Building a More Sustainable Factory Floor Leveraging Smart Manufacturing

Auto manufacturers are adopting smart manufacturing strategies to modernize facilities and improve the sustainability of their operations.

Enabling Greatly Needed Flexibility with Smart Manufacturing

While most associate smart manufacturing with improvements in operational efficiencies and faster time to market, the same principles and solutions deliver the flexibility to adapt to market changes.

What’s Next for Smart Factories? A Look Ahead to Industry 5.0

Industry 5.0 builds on the technologies of Industry 4.0 but emphasizes sustainability and the collaboration between humans and machines.

Addressing a Fact of Life: Compressed Development and Launch Times in Auto Manufacturing

Automakers can successfully address compressed development and launch timelines by embracing Agile methodologies, advanced digital tools, and flexible supply chain strategies.

Human-robot Collaboration and Smart Manufacturing

Virtual commissioning and digital twins can help automakers and their Tier 1 parts suppliers ensure that their human-robot collaboration projects achieve their desire objectives without posing a safety threat to the human operators.

2024 Automotive Smart Manufacturing Trends

There is no question that auto manufacturers will rely on smart manufacturing strategies and solutions in the coming year. Here are some trends to look for in 2024.

The Value of Smart Manufacturing in Automotive

In a world racing towards the future, automotive leaders are not just keeping pace but setting the speed..

Smart Manufacturing for Automotive and Transportation

Drive operational excellence with intelligent technologies and advanced automation Navigate rapid change and achieve operational excellence by embracing smart manufacturing for next-level automation, and production excellence.

Digital Twins and Other Tech Enable Virtual Commissioning

Virtual commissioning saves time and money, and it avoids interruptions of existing work cells, production lines, and plants.

Researchers Amplify Impact of Generative AI in Auto Design

A new technique allows designers to add engineering constraints into the text-to-image generative AI process, cutting down the iterations needed to address design considerations.

A Deep Dive into Virtual Commissioning

Virtual commissioning uses digital twins, sophisticated simulations, and modeling to help manufacturers adjust to changes and modernize their operations.

The Value of Virtual Manufacturing Engineering

Guarantee a flawless launch with virtual manufacturing. Simulate your entire production line virtually, identifying issues before physical commissioning. This virtual environment lets all your engineers collaborate seamlessly, driving sustainability in the manufacturing process.

Virtual Manufacturing Engineering for the Automotive Industry

How can you guarantee the launch of a plant with safe, efficient, and sustainable production through upfront validation of the design and manufacturing processes?

Enable virtual development to achieve smart manufacturing in automotive

In this webinar, discover the many benefits of virtually developing your manufacturing line and how this allows manufacturers to optimize it before going into operation, so it runs right the first time—leading to a flawless launch of your line.

Integrated manufacturing process planning for the automotive industry

As new vehicles become increasingly software-defined, they pose new design challenges for automakers. How will they accelerate their product engineering and manufacturing and get it right the first time?

Teamcenter X for automotive manufacturing

Teamcenter X Manufacturing can address complex automotive manufacturing challenges without the time and expense required to deploy it while getting users up and running fast. Learn more in this infographic.

The Automotive Executive’s Guide to Digital Manufacturing

Learn how to virtualize your product launches and predict potential issues before they arise. By building a digital twin of production and performance, you’ll achieve digital continuity—from design to delivery.

Do you have control of your automotive MBOM?

Learn how you can get a better handle on your automotive manufacturing bill of materials (MBOM) to reduce risk and costly errors in this Siemens.com blog post.

Maximize efficiency and quality with simulation-based manufacturing process planning

Integrated collaboration can transform your manufacturing process by enabling early validation and design issue resolution with collaborative manufacturing planning, reducing errors and improving efficiency with integrated work instruction creation, and more.

Staying Competitive with Rapid Auto Plant Transformation

To keep pace with evolving customer demands and market changes, auto manufacturers must adopt smart manufacturing solutions that allow them to rapidly transform their production facilities.

Rapid factory evolution for the automotive industry

In this webinar, learn about Smart Manufacturing solutions for automotive manufacturers that can help modernize their existing OT/IT landscape with minimal downtime and costs while achieving improved operational transparency, driving faster cycle times and improving quality.

Achieve a rapid plant evolution with Smart Manufacturing solutions

Discover how OEMs and suppliers can transform automotive production planning and processes with smart manufacturing solutions for rapid factory evolution, featuring Siemens case studies from BAIC BJEV, Porsche, and Volkswagen.

Accelerating Innovation: How Virtual Development Mitigates Rapid Change in Auto Manufacturing

Virtual development is a tool for innovation and efficiency and will continue to be a cornerstone in the evolution of auto manufacturing, shaping the vehicles of tomorrow and the processes that create them.

The Value of Rapid Factory Transformation

By updating legacy equipment, you can gain actionable insights into production and accelerate the modernization of your plant. Transform your production facilities to monitor and predict operational performance in real time, reducing downtime and increasing efficiency.

Enabling the Acceleration of Factory Conversion to Smart Factories

RTInsights talks with Siemens about the need to convert to smart factories, the technologies that can help, and the benefits that automakers can derive from making the change.

Driving Toward Industry 5.0: An Automotive Manufacturing Perspective

Industry 5.0 represents more than just a technological shift; it’s a philosophical change in how the industry views manufacturing. It demands that automakers blend innovation with empathy, efficiency with sustainability, and precision with creativity.

Unlocking the Potential of Intelligent Production in Auto Manufacturing

At the core of intelligent production environments is the ability to monitor and adjust manufacturing processes in real time.

Why Automakers Need Intelligent Manufacturing Operations

Intelligent manufacturing solutions let companies react faster to issues on a production line or plant and to changing market conditions.

How AI-Driven Feedback Loops Make Car Manufacturing More Competitive

Integrating artificial intelligence (AI) into feedback-driven processes pushes the boundaries of what’s possible in automotive manufacturing.

Virtualizing the Automated Assembly Line

Automotive assembly line virtualization involves the use of digital tools and techniques to model, simulate, optimize, and manage assembly processes before they’re physically implemented.

Manufacturers Embrace Digital Twins for Enhanced Production

Manufacturers are looking into digital twins as a way to reduce the costs of commissions and improve client relations.

Why Auto Makers Must Move to Intelligent Manufacturing Operations

A discussion about the factors driving the need for smart manufacturing, key technologies that help auto manufacturers make that change, and the benefits they will realize in using the technologies and solutions.

Drive Quality and Sustainability Through Intelligent Production

While automotive manufacturers adopt IoT, AI, and machine learning, unlocking their full potential requires extracting actionable data insights for optimized production, reduced waste, and sustainability.

The Value of Intelligent Production Excellence

Harness the power of data, monitor performance, and address operational issues in real-time. Transform your production facilities into intelligent plants with smart manufacturing solutions.

Transform Your Plant with the Next Level of Smart Manufacturing

Explore case studies from two automotive powerhouses; Porsche and Volkswagen and learn how they were able to set new standards in automotive production.

How Human-Machine Collaboration Fuels Consumer-Driven Manufacturing

Human-machine collaboration in smart manufacturing drives consumer-focused innovation, enabling personalized designs, sustainable practices, and faster production.

In-Cabin Sensing has Automakers Looking Inward

In 2025, in-cabin sensing is the underlying foundation needed for legal compliance, semi-autonomous driving, safety ratings, and the premium user experience consumers now expect.

Production Operation and Optimization for Automotive

The rising complexity in automotive production requires flexibility, scalability, faster time-to-market and sustainability in the shopfloor operations. It needs next-level automation.

Making Smart Manufacturing Smarter with AI

By integrating AI, automakers not only streamlining their operations but also lay the groundwork for transformative changes in the industry.

Electric Car Factory for China’s Sales Champion

The sales champion of China’s electric vehicle market, BAIC BJEV, has built the group’s first mass production base for energy vehicles. To strengthen the brand, improve product quality, and produce vehicles that can even better meet the market’s needs, the company turned to Siemens hardware and software and its SICAR standard for the automotive industry.

The first fully digital automotive factory in South East Asia

As a member of Vingroup, one of Vietnam’s largest privately held companies, VinFast teamed up with car manufacturers from America, Europe and Siemens to build their automotive factory in only 21 months. The holistic Siemens Xcelerator portfolio helped realizing the ambitious goal.

Advanced strategies for line automation engineering in automotive

Learn how to overcome industry challenges and stay ahead with proven strategies for next-level automation, virtual verification, and data-driven production, in this eBook.

Resources

Transform Your Plant with the Next Level of Smart Manufacturing

Explore case studies from two automotive powerhouses; Porsche and Volkswagen and learn how they were able to set new standards in automotive production.

The Value of Rapid Factory Transformation

By updating legacy equipment, you can gain actionable insights into production and accelerate the modernization of your plant. Transform your production facilities to monitor and predict operational performance in real time, reducing downtime and increasing efficiency.

Smart Manufacturing in the Automotive Industry

Learn how auto manufacturers are addressing various challenges they face with smart manufacturing in this state of the market report.

The Value of Intelligent Production Excellence

Harness the power of data, monitor performance, and address operational issues in real-time. Transform your production facilities into intelligent plants with smart manufacturing solutions.

Enabling the Acceleration of Factory Conversion to Smart Factories

RTInsights talks with Siemens about the need to convert to smart factories, the technologies that can help, and the benefits that automakers can derive from making the change.

Human-robot Collaboration and Smart Manufacturing

Virtual commissioning and digital twins can help automakers and their Tier 1 parts suppliers ensure that their human-robot collaboration projects achieve their desire objectives without posing a safety threat to the human operators.

Addressing a Fact of Life: Compressed Development and Launch Times in Auto Manufacturing

Automakers can successfully address compressed development and launch timelines by embracing Agile methodologies, advanced digital tools, and flexible supply chain strategies.

2024 Automotive Smart Manufacturing Trends

There is no question that auto manufacturers will rely on smart manufacturing strategies and solutions in the coming year. Here are some trends to look for in 2024.

A Deep Dive into Virtual Commissioning

Virtual commissioning uses digital twins, sophisticated simulations, and modeling to help manufacturers adjust to changes and modernize their operations.

Why Auto Makers Must Move to Intelligent Manufacturing Operations

A discussion about the factors driving the need for smart manufacturing, key technologies that help auto manufacturers make that change, and the benefits they will realize in using the technologies and solutions.

Accelerating Innovation: How Virtual Development Mitigates Rapid Change in Auto Manufacturing

Virtual development is a tool for innovation and efficiency and will continue to be a cornerstone in the evolution of auto manufacturing, shaping the vehicles of tomorrow and the processes that create them.

What’s Next for Smart Factories? A Look Ahead to Industry 5.0

Industry 5.0 builds on the technologies of Industry 4.0 but emphasizes sustainability and the collaboration between humans and machines.

Enabling Greatly Needed Flexibility with Smart Manufacturing

While most associate smart manufacturing with improvements in operational efficiencies and faster time to market, the same principles and solutions deliver the flexibility to adapt to market changes.

Building a More Sustainable Factory Floor Leveraging Smart Manufacturing

Auto manufacturers are adopting smart manufacturing strategies to modernize facilities and improve the sustainability of their operations.

Not Your Father’s Auto Industry: Why Smart Manufacturing is Needed as We Head into 2024

Smart manufacturing technologies like digital twins, virtual commissioning, and more can bring about the required changes to move the industry forward in the years to come.

How Smart Technologies are Helping Simplify Sustainability in Auto Manufacturing

Smart technologies are emerging as a powerful simplifying force amid the complexities of pursuing sustainability goals.

How Smart Manufacturing Makes Smart Autos Possible

Automakers are using virtual commissioning, digital twins, advanced supply chain management, and more to meet ever-changing customer demands for smart autos.

Smart Manufacturing Essential for the Transition to EVs

Many of the broad range of technologies (e.g., digital twins, virtualization, and more) that help auto manufacturers enable intelligent or smart manufacturing operations can play a role in the transition to EVs.

How AI-Driven Feedback Loops Make Car Manufacturing More Competitive

Integrating artificial intelligence (AI) into feedback-driven processes pushes the boundaries of what’s possible in automotive manufacturing.

Virtualizing the Automated Assembly Line

Automotive assembly line virtualization involves the use of digital tools and techniques to model, simulate, optimize, and manage assembly processes before they’re physically implemented.

Manufacturers Embrace Digital Twins for Enhanced Production

Manufacturers are looking into digital twins as a way to reduce the costs of commissions and improve client relations.

You Can’t Spell Smart Manufacturing Without AI

AI helps smart manufacturers use the vast amounts of data being generated from IoT devices and smart sensors throughout their factory.

Smart Factory Modernization Improves Efficiency

The automotive industry’s embrace of smart factory modernization will revolutionize production processes (and, in many cases, already has), enabling real-time monitoring, predictive maintenance, and optimized workflows.

IoT Connections To Grow by 400% In Four Years

IoT connections are expected to reach 142 million by 2027, primarily due to the growth in 5G standalone deployments.

Researchers Amplify Impact of Generative AI in Auto Design

A new technique allows designers to add engineering constraints into the text-to-image generative AI process, cutting down the iterations needed to address design considerations.

Smart Manufacturing: Melding Digital and Physical Worlds

Smart manufacturing helps automakers achieve greater efficiency and accelerate innovation by blending digital technologies with the physical realm, making it possible to accomplish things we’ve never seen before.

Digital Twins and Other Tech Enable Virtual Commissioning

Virtual commissioning saves time and money, and it avoids interruptions of existing work cells, production lines, and plants.

Why Automakers Need Intelligent Manufacturing Operations

Intelligent manufacturing solutions let companies react faster to issues on a production line or plant and to changing market conditions.

Riding Out Automotive Market Uncertainty with Digital Twins

A critical aspect of using digital twins is that they can complement traditional forecasting and prescriptive tools by incorporating real-time monitoring and simulations.

Digital Twins, IT/OT Convergence Drive the Industrial Internet

Digital twins offer a way to apply advanced analytics to derive insights that, in turn, drive optimization of production and operation processes.

Using Fuzzy Logic and AI to Improve Supply Chain Efficiency

The integration of fuzzy logic and AI presents significant opportunities for organizations like smart automotive manufacturers to enhance their supply chain management practices.

Drive Quality and Sustainability Through Intelligent Production

While automotive manufacturers adopt IoT, AI, and machine learning, unlocking their full potential requires extracting actionable data insights for optimized production, reduced waste, and sustainability.

The Value of Virtual Manufacturing Engineering

Guarantee a flawless launch with virtual manufacturing. Simulate your entire production line virtually, identifying issues before physical commissioning. This virtual environment lets all your engineers collaborate seamlessly, driving sustainability in the manufacturing process.