Automakers are using virtual commissioning, digital twins, advanced supply chain management, and more to meet ever-changing customer demands for smart autos.

The automotive market is undergoing rapid and significant changes. Cars are getting smarter, and customers are demanding access to new technologies as they emerge. Increasingly, automakers are relying on smart manufacturing to make this happen.

A look at some industry statistics helps put the challenges the industry faces into perspective and highlights the areas where smart manufacturing is being used. With that said, here are some points to consider:

Smart factory market size: There are numerous estimates and projections for the size of the smart manufacturing market. All point to robust growth. For example, Verified Market Research valued the market at $327.12 Billion in 2022 and projects it will reach $863.48 Billion by 2030, growing at a CAGR of 12.90% from 2023 to 2030.

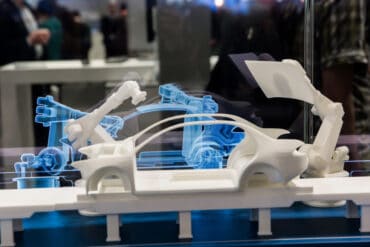

Digital twins: Virtual representations via digital twins of everything from a single machine on an assembly line, a work cell, a single production line, or an entire factory offer manufacturers many benefits. A recent industry survey found that the use of digital twins is “on the rise to optimize areas like performance and quality control” and that respondents “noted almost unanimously how digital twinning has provided greater productivity and cost savings, among several other advantages.”

Chips power smart auto advances; shortages need intelligent supply chains: Many features of modern autos, like assisted driving, occupant comfort, performance, safety, and more, are possible via microprocessors. In fact, an average car today has between 1,400 and 1,500 semiconductor chips. Unfortunately, chip supplies have been impacted by lingering supply chain issues that started during the pandemic and, more recently, by geopolitical issues. That forced many automakers to curtain production or ship cars without the features missing chips powered. These issues have raised the importance of more proactive and advanced supply chain management within the smart manufacturing umbrella.

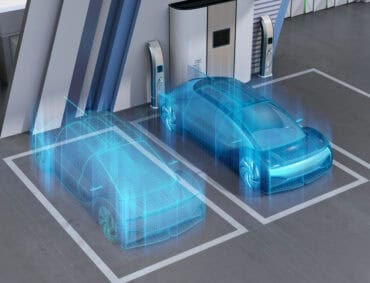

Electric vehicles on the rise: The global sale of electric vehicles boomed in the fist half of the year. One report found that a total of 6 million new Battery Electric Vehicles (BEV) and Plug-in Hybrids (PHEVs) were delivered during the first half of 2023. That represented a more than 40% increase over the same period the year before. The following months had similarly large growth rates.

Driverless cars take to the roads: While many states, countries, and regions limit driverless cars on their roads, many are being approved for use with certain restrictions. Currently, there are more than 30 million autonomous cars in the world. The market is predicted to grow from an estimated $33.48 billion in 2023 to reach $93.31 billion by 2028. That represents at a CAGR of 22.75% during the forecast period (2023-2028).

Vehicle-to-vehicle (V2V) communication is on the horizon: City planners, government agencies, traffic management groups, and more are all eyeing the potential benefits vehicle-to-vehicle communications can bring once widely available. V2V technology can potentially be used to help ease traffic congestion, improve the environment, and avoid crashes. To that point, the U.S. Department of Transportation’s National Highway Traffic Safety Administration (NHTSA) estimates that 615,000 motor vehicle crashes could be prevented using V2V technology.

See also: Not Your Father’s Auto Industry: Why Smart Manufacturing is Needed as We Head into 2024

A final word on smart autos and the role of smart manufacturing

Changes in the automotive market are happening at a dizzying pace. Meeting customer demands for electric cars, driverless cars, and regular cars with advanced features requires major changes in the end-to-end production lifecycle. Everything, including sourcing materials, incorporating new technologies in the design phase, building the cars, and supporting them after they roll off the assembly line, is different than it has been in the past.

Smart manufacturing helps in all these areas. Specifically, automakers are using virtual commissioning, digital twins, advanced supply chain management, and more to meet ever-changing customer demands.

Additional Resources

Drive production excellence with intelligent manufacturing

The automotive industry is facing unprecedented challenges, with rapid change and intense pressure to meet the demands of climate change, regulations, and consumers. Download Now

Modernize automotive factories with Siemens Smart Manufacturing solutions

Discover how automakers can transform their business with Smart Manufacturing solutions using state-of-the-art hardware and software to modernize production lines. Watch Now

Virtual Manufacturing Development for the Automotive Industry

Companies in the automotive industry are pushing to develop the next generation of autonomous, electric, connected, and shared vehicles. View Now