Enterprise industrial connectivity offers a way to address manufacturing digital transformation data integration challenges by enabling seamless communication across disparate systems.

In today’s fast-paced industrial environment, digital transformation has become imperative for manufacturers seeking to stay competitive and improve operational efficiency. However, there are many obstacles to digital transformation. Specifically, many manufacturers must deal with legacy systems, siloed operations, and proprietary communications protocols commonly found in operational technology (OT) systems.

These factors create barriers to integrating data and achieving the real-time insights needed to modernize manufacturing operations. Enterprise industrial connectivity offers a way to address these challenges by enabling seamless communication across disparate systems.

The Challenges of Digital Transformation in Manufacturing

Manufacturers pursuing digital transformation must address several hurdles that can slow down or even stall their efforts – especially when trying to scale. One of the primary challenges is the existence of siloed systems. Traditionally, manufacturing environments consist of a mix of systems and equipment from different vendors, each with its own communication protocols. This diversity in protocols can make it difficult to achieve interoperability and integration across the plant floor.

Why is this an issue? OT systems, such as programmable logic controllers (PLCs), sensors, and other machinery, often communicate using protocols that are not readily compatible with IT systems or with equipment from other vendors. This lack of compatibility leads to isolated data silos, where valuable operational data cannot be easily accessed or utilized across the organization.

Furthermore, the lack of standardized connectivity increases the need for custom integrations to facilitate communication between systems. Custom integrations and/or point-to-point connectivity solutions can be time-consuming and costly, often requiring specialized expertise to implement and maintain. This dependency on custom solutions not only drives up costs but also limits flexibility and scalability in the long run.

The Role of Enterprise Industrial Connectivity in Digital Transformation

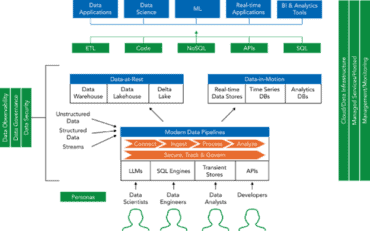

Standard-based connectivity provides a framework for overcoming these challenges by enabling seamless communication across OT and IT systems. By adopting standard communication protocols, manufacturers can achieve enhanced interoperability, allowing different systems and devices to exchange information without the need for complex custom integrations.

Enhanced Interoperability and Reduced Integration Complexity

One of the most significant benefits of standard-based connectivity is the reduction in integration complexity. By using standard protocols, manufacturers can connect various systems, such as machines, sensors, and control systems, without the need for custom code or proprietary adapters. This simplifies the integration process and enables quicker deployment of new technologies, ultimately reducing time-to-value for digital transformation initiatives.

Improved Data Flow and Real-Time Data Exchange

Standardized connectivity facilitates real-time data exchange across systems, enabling manufacturers to access accurate and timely data. This improved data flow is crucial for initiatives such as predictive maintenance, process optimization, and quality control, which rely on real-time insights to drive decision-making. With standard-based connectivity, data from disparate systems can be consolidated, analyzed, and used to optimize operations and improve overall efficiency.

Cost and Time Efficiencies

The use of standardized protocols and tool sets can also lead to significant cost and time savings. By reducing the need for custom integrations, manufacturers can avoid the expense of hiring specialized personnel to implement and maintain these solutions. Additionally, standardized connectivity allows for quicker upgrades and modifications to the system, providing manufacturers with the flexibility to adapt to changing business requirements and technological advancements. Furthermore, standardized connectivity can help manufacturers consolidate vendors. That, in turn, helps lower TCO as complexity is reduced and management is made easier.

Enhanced Data Quality and Accessibility

Standard-based connectivity improves data accessibility and reliability, ensuring that accurate information is available when needed. Enhanced data quality is critical for making informed decisions and optimizing operations. With standardized connectivity, manufacturers can ensure that data from various sources is consistent and reliable, reducing the risk of errors and enabling more precise analysis and reporting.

See also: Enabling IT/OT Convergence and Its Many Benefits

How PTC Kepware Solutions Accelerate Digital Transformation

While standard-based connectivity provides the foundation for digital transformation, implementing these standards across an industrial organization requires expertise and time. Many organizations may not have either. This is leading many manufacturers to team up with a technology partner that not only brings solutions but also deep industry-specific expertise to address the specific connectivity problems manufacturers face.

Those are all areas where PTC can help. PTC Kepware, part of PTC’s suite of industrial solutions, offers a robust and flexible platform for achieving standard-based connectivity in manufacturing environments – and the ability to connect to diverse devices in minutes.

Recently, PTC Kepware launched Kepware+, an enterprise industrial connectivity solution designed to connect, manage, monitor, and control diverse automation devices at scale. The platform is built around the Kepware KEPServerEX, its connectivity solution that supports more than 300 protocols, including OPC (Open Platform Communications) and MQTT (Message Queuing Telemetry Transport). Its support for multiple protocols allows manufacturers to connect and integrate a wide range of devices, regardless of vendor or protocol.

Key Features and Capabilities

PTC Kepware is known for its flexibility and scalability, offering a range of features that support manufacturers in their digital transformation efforts:

- Broad Protocol Support: Kepware supports over 300 communication protocols via 150+ drivers, enabling connectivity across diverse devices.

- Interoperability with OT and IT Systems: By facilitating communication between OT and IT environments, Kepware helps manufacturers bridge the gap between production operations and enterprise systems.

- High Performance and Reliability: Kepware’s platform is designed for industrial environments, offering high reliability and performance to ensure data integrity and uptime.

- Ease of Integration and Scalability: With an intuitive user interface and scalable architecture, Kepware makes it easy for manufacturers to deploy and expand their connectivity solutions as needed.

Benefits Abound

For manufacturers aiming to accelerate their digital transformation, PTC Kepware provides several key benefits:

- Simplified Connectivity Across Disparate Systems: Kepware’s support for multiple protocols allows manufacturers to easily connect systems from different vendors, simplifying integration and reducing the need for custom solutions.

- Real-Time Data Access and Enhanced Decision-Making: With Kepware, manufacturers can access real-time data from various sources, enabling data-driven decision-making and optimizing operations for improved efficiency and productivity.

- Reduced Costs and Increased Flexibility: By streamlining integration and providing a scalable platform, Kepware helps manufacturers reduce costs associated with custom integrations and allows them to adapt their connectivity solutions to meet evolving business needs.

A Final Word on the Need for Enterprise Industrial Connectivity to Accelerate Digital Transformation

As manufacturers continue to pursue digital transformation, enterprise industrial connectivity remains a critical component of their strategy. By enabling interoperability, improving data flow, and reducing integration costs, enterprise connectivity helps manufacturers overcome the challenges of siloed systems and proprietary protocols. PTC Kepware offers a powerful platform to support these efforts, providing manufacturers with the tools they need to connect, manage, and optimize their operations. With PTC Kepware, manufacturers can accelerate their digital transformation journey, leveraging real-time data and insights to drive operational excellence and stay competitive in today’s dynamic industrial landscape.