As IoT technology increases, the potential for IoT analytics in industrial operations will only grow, offering even more opportunities for innovation and optimization.

In recent years, the industrial sector has undergone a significant transformation thanks to the pervasive use of the Internet of Things (IoT). IoT devices have become an integral part of industrial environments, collecting data from equipment, sensors, and machinery across various processes. While the adoption of IoT devices alone has brought substantial improvements, it’s the power of IoT analytics that truly drives operational excellence.

By processing and analyzing the data gathered from IoT devices, industrial managers can make informed decisions that lead to improved operational efficiency, increased productivity, reduced downtime, and more.

Modern IoT analytics makes use of advanced data analysis tools, AI, and techniques to the vast amounts of data generated by IoT devices. In an industrial setting, this data can include anything from equipment performance metrics to environmental conditions, as well as production metrics. The value of IoT analytics lies in its ability to convert raw data into actionable insights.

The process generally involves data collection, storage, processing, and analysis. With advancements in cloud computing and edge computing, the industrial sector can now analyze data in near real time, allowing for quicker response times and more agile decision-making.

Increasingly, industrial IoT analytics employs machine learning and artificial intelligence to uncover patterns, predict outcomes, and suggest optimized actions.

See also: New IoT Use Cases Improve Industrial Manufacturing Operational Efficiency

Boosting Operational Efficiency with IoT Analytics

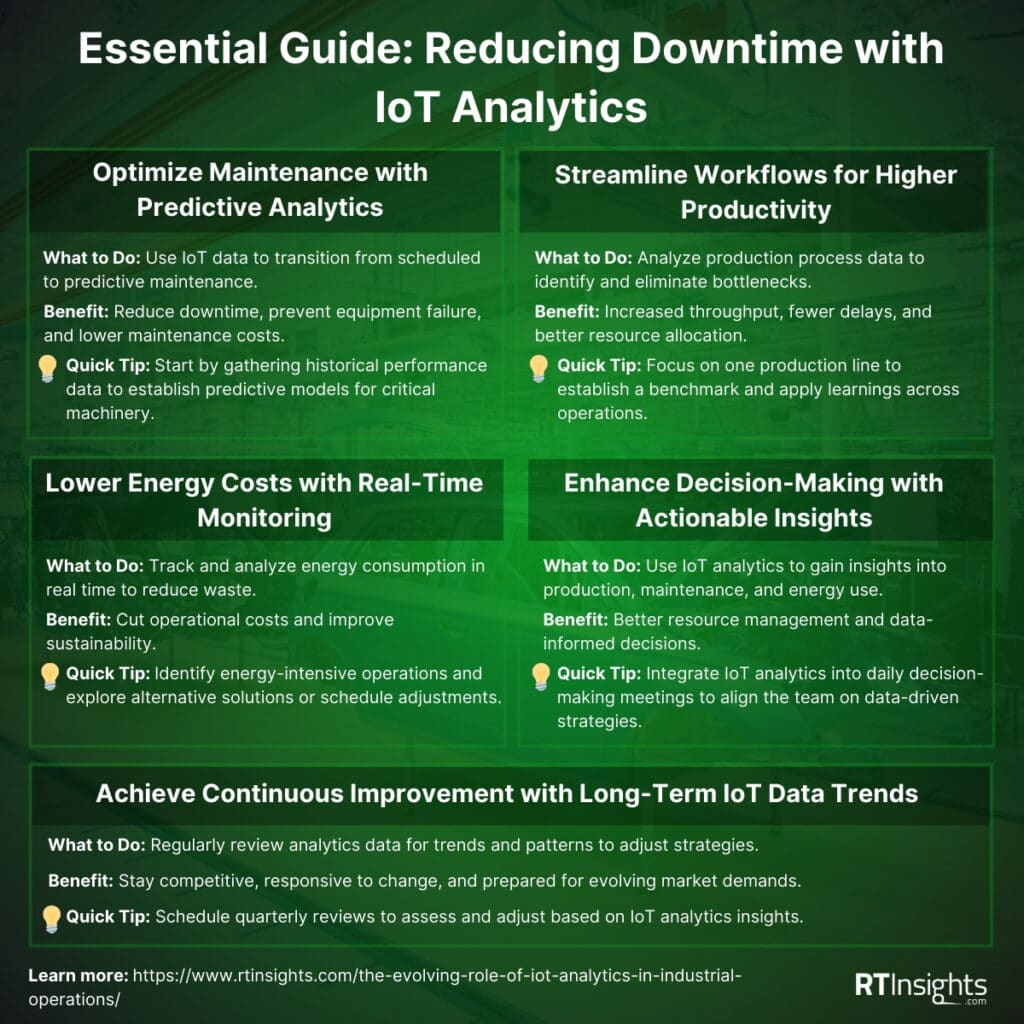

One of the primary benefits of IoT analytics in the industrial sector is its potential to improve operational efficiency. With real-time data on machinery and production processes, industrial managers can identify bottlenecks, streamline workflows, and optimize resource allocation.

For example, predictive analytics can forecast potential maintenance needs by analyzing historical performance data and equipment conditions in real time. Instead of relying on periodic maintenance schedules, which can be inefficient and costly, managers can use data-driven insights to perform maintenance only when necessary, reducing unnecessary downtime and maximizing equipment utilization.

Moreover, IoT analytics enables industrial managers to track the energy consumption of various machines and processes. By identifying energy-intensive activities, managers can implement strategies to reduce energy usage and lower operational costs. As industries increasingly focus on sustainability, the role of IoT analytics in optimizing energy consumption is becoming more critical.

Enhancing Productivity with IoT Analytics

Another common use case for IoT analytics is to improve productivity by providing insights that help managers make faster and more accurate decisions. For example, it can help optimize inventory levels by predicting supply and demand trends, ensuring that resources are available when needed without overstocking.

In a production line, analyzed data from IoT sensors can monitor each step of the manufacturing process in real time. By analyzing this data, managers can identify stages where delays are common and implement solutions to minimize downtime. This proactive approach to problem-solving helps to maintain a steady production flow, resulting in higher productivity and output.

See also: The Evolution of Manufacturing in the IoT Era

Reducing Downtime

Downtime is one of the most significant challenges in industrial operations, leading to lost revenue and decreased productivity. Analyzed data from IoT sensors can help minimize both planned and unplanned downtime. Through predictive maintenance, it can identify potential equipment failures before they occur. This proactive approach enables maintenance teams to address issues during scheduled downtimes or shifts, reducing the likelihood of unexpected interruptions.

IoT analytics can also monitor the health and performance of machinery in real time. If a machine starts to show signs of wear or unusual behavior, the analytics system can immediately alert the maintenance team, allowing them to take corrective action before the issue escalates. This level of visibility ensures that equipment operates smoothly and consistently, reducing the frequency and duration of downtime.

Additionally, IoT analytics can help optimize the supply chain by providing insights into potential disruptions. By analyzing data on supplier performance, transportation routes, and inventory levels, industrial managers can make adjustments to mitigate the impact of delays or shortages. This predictive capability enhances the resilience of industrial operations, ensuring continuity even in the face of unforeseen challenges.

Driving Continuous Improvement

Beyond immediate operational benefits, IoT analytics fosters a culture of continuous improvement. By consistently analyzing data and refining processes, industrial managers can stay ahead of the competition and adapt to changing market demands. It can help identify long-term trends and patterns that may not be immediately apparent, enabling managers to make strategic decisions that drive sustained growth.

For example, IoT analytics can reveal insights into customer behavior and preferences, helping industrial managers tailor their products and services to meet evolving needs. By understanding these trends, companies can invest in innovation and R&D efforts that align with market demands, ensuring that they remain competitive in the long run.

A Final Word

IoT analytics enables data-driven decision-making that enhances operational efficiency, boosts productivity, reduces downtime, and promotes continuous improvement. As IoT technology continues to evolve, the potential for IoT analytics in industrial operations will only grow, offering even more opportunities for innovation and optimization.

For industrial managers, embracing IoT analytics is not just a trend; it’s a strategic imperative. By leveraging the power of IoT analytics, industrial companies can stay competitive, improve their bottom line, and pave the way for a more sustainable future.