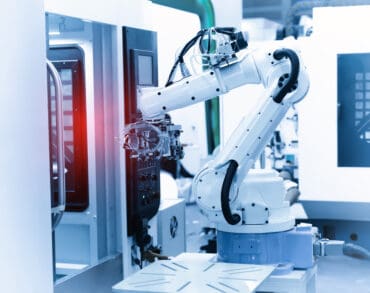

New IoT use cases help industrial manufacturers achieve greater operational efficiency, reduce costs, and enhance overall productivity.

Industrial manufacturers have long used the Internet of Things to keep production lines running smoothly and operating efficiently. Now, many are expanding their use of IoT to support new cases.

Traditional use of IoT has been to monitor the health of production line equipment. Over time, more sophisticated applications like predictive maintenance and real-time data analytics of IoT data to optimize production processes, identify bottlenecks, and improve overall equipment effectiveness (OEE), were adopted.

More recently, additional use cases have become more common. Examples include:

Asset tracking and management: IoT devices can help optimize supply chains by tracking the location and status of assets, ensuring better inventory management, and reducing delays.

Improved resource utilization: IoT devices can be used to monitor the usage and location of tools and machinery to maximize their utilization and reduce idle time.

Assist energy management: IoT sensors can monitor and control energy usage across the manufacturing facility, leading to significant energy savings and reduced costs.

Environmental monitoring: IoT devices can monitor environmental conditions such as temperature, humidity, and air quality to ensure optimal conditions for production processes and worker safety.

Enhanced quality control: IoT-enabled cameras and sensors can perform real-time quality inspections during the production process, ensuring defects are caught early.

Data-driven quality assurance: IoT data can be used to analyze trends and patterns in product quality, leading to continuous improvement in manufacturing processes.

See also: The Evolution of Manufacturing in the IoT Era

New IoT use cases abound

As IoT devices become more pervasive throughout industrial manufacturing plants and processes, ever-more sophisticated use cases are starting to emerge. Many of the new applications need enterprise connectivity solutions that help provide access to the IoT data from disparate devices and systems.

Once that access is assured, more things can be done with the data to support different operational and functional areas.

One particularly interesting emerging application is condition-based maintenance (CBM). Similar to the way IoT data is used for predictive maintenance, CBM’s aim is to use specific device or equipment performance metrics to spot and fix potential issues before a problem occurs.

One area of focus for CBM is vibration and temperature monitoring. Here, a manufacturer would use IoT sensors to monitor the condition of critical components like motors and bearings, scheduling maintenance based on actual wear and tear rather than fixed schedules.

Another focus of CBM is on oil and fluid analysis. Here, IoT data allows for the continuous monitoring of oil and other fluids to ensure optimal performance and early detection of potential issues.

Those are just the tip of the iceberg. Some examples of what is possible when an industrial manufacturer combines IoT and enterprise connectivity include:

Remote equipment management: Engineers can monitor and control machinery from remote locations, enabling quicker response times and reducing the need for on-site visits.

Distributed manufacturing: Staff can coordinate production across multiple locations through IoT, ensuring consistent quality and efficiency.

Automated replenishment: IoT sensors can trigger automatic replenishment of materials and components based on real-time usage data, thus keeping production lines and processes running without interruption.

Fleet management: IoT devices can track the location, condition, and performance of vehicles delivering raw materials, optimizing routes, and reducing fuel consumption.

Cold chain monitoring: IoT devices can monitor environments during transportation to ensure the integrity of temperature-sensitive products.

By leveraging these new capabilities and use cases, industrial manufacturers can achieve greater operational efficiency, reduce costs, and enhance overall productivity.